PERWIN adopts advanced design concepts and working principles, it makes the filling production line equipment for eye care liquid products more perfect and reliable through the continuous practice of a large number of professional users of the company and the continuous improvement and integration of professional technical parameters. It is suitable for the filling and production of various bottle-shaped and various specifications of eye care solution.

● Design the production line according to the user's process requirements.

● According to users' needs, provide production line cleaning (CIP) and in-line sterilization (SIP) technology and configuration.

Production line features:

● According to user's needs and the characteristics of the bottle type, different schemes can be adopted for the bottle feeding method.

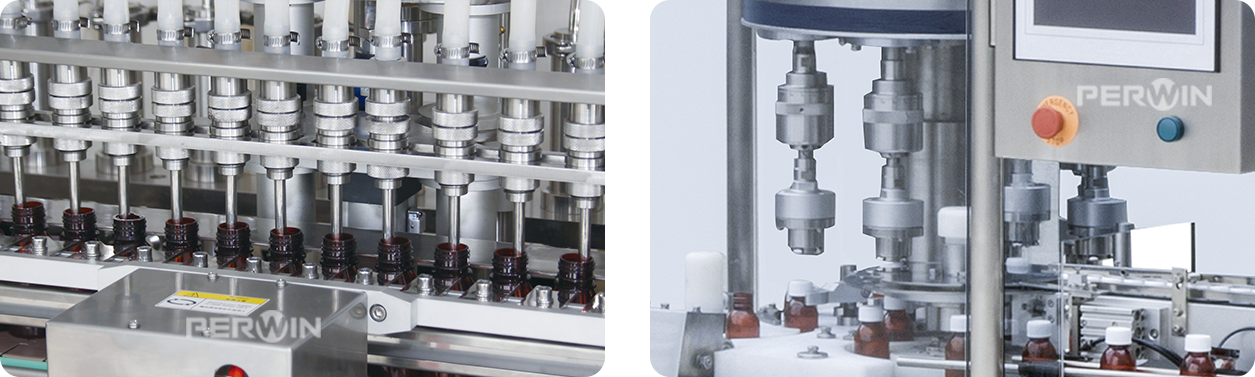

● Use stainless steel 316L piston pump, ceramic plunger pump and peristaltic pump or the method specified by the user for precise filling, filling accuracy: ±0.5~1%.

● Specially designed inlet and outlet check valve design and precise processing methods ensure 100% no dripping during filling.

● When the equipment is working, the filling needle can be lifted up and down or submerged to prevent liquid from foaming or splashing.

● The specially designed servo technology or magnetic induction technology controls the capping torque and the flexible connection of the press-screw buffer capping scheme to ensure stable capping torque, no damage to the cap, and stable and reliable capping quality.

● The overall linkage line is intelligently controlled, and the operation of upstream and downstream equipment has the function of interlocking control.

● It has the function of online automatic rejection of products without caps (customer purchase).

● The overall linkage line is intelligently controlled, and the operation of upstream and downstream equipment has the function of interlocking control.

Production capacity:

40~50 bottles/min, 80~120 bottles/min, 120~200 bottles/min (different production line schemes, different production capacities).