PERWIN adopts advanced design concepts and working principles, it makes the eye drop filling production line equipment more perfect and reliable through the continuous practice of a large number of professional users and the continuous improvement and integration of professional technical parameters. It is used for filling and production of eye drops of various specifications and bottle types.

Production line features:

● According to the user's needs and the characteristics of the bottle type, different schemes can be adopted for the bottle feeding method.

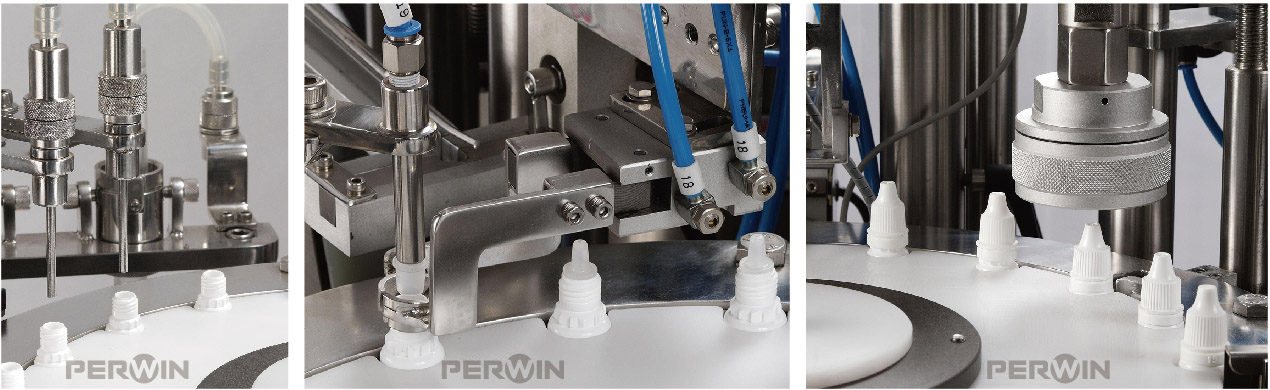

● Use ceramic plunger pump, peristaltic pump or user-specified method for precise filling, filling accuracy: ±0.5~1%.

● Professional inlet/outlet check valve design to ensure no leakage during filling.

● The specially designed servo technology or magnetic induction technology controls the capping torque and the flexible connection of the press-screw buffer capping solution to ensure stable capping torque, no damage to the cap, and stable and reliable capping quality.

● It has the function of online automatic rejection of products without plugs and caps (customer purchase).

● Customers can choose the online automatic identification and elimination (or alarm shutdown) function of capping defects such as no cap and crooked cap.

● The main body of the equipment is made of stainless steel SUS 304#, aluminum alloy, non-toxic polymer materials, etc. The parts in contact with the liquid are made of pharmaceutical grade polymer materials or 316L stainless steel materials, and the overall production line equipment meets GMP requirements.

● Customers can choose CIP or SIP function and mechanism unit, or 100-level laminar flow hood.

● 40~50 bottles/min, 60~120 bottles/min, 120~200 bottles/min can be customized according to customer requirements (different production line schemes, different production capacities).